Out of Lab to Production Facility: An Vital Use of Vacuum Fittings in Industrial Settings

In the field of commercial production, maintaining seamless operational effectiveness is paramount. One of the hidden heroes in achieving this aim is the vacuum flange, a uncomplicated yet essential component in various applications. Vacuum flanges play a critical role in establishing airtight seals that stop contamination and maintain the integrity of systems operating under low-pressure conditions. From research laboratories to large-scale production facilities, these components are essential in ensuring maximum conditions for a range of processes.

As fields continue to develop and leverage advanced technologies, the role of vacuum flanges has become even more pronounced. Whether in semiconductor fabrication, pharmaceutical manufacturing, or materials processing, the demand for reliable vacuum systems has surged. The effectiveness of these systems heavily depends on the efficiency of vacuum flanges, making them a central element in discussions about performance, safety, and effectiveness. Understanding their applications and importance in different sectors helps illuminate their essential role in bridging the chasm between lab innovations and factory realities.

Understanding Negative Pressure Flange Components

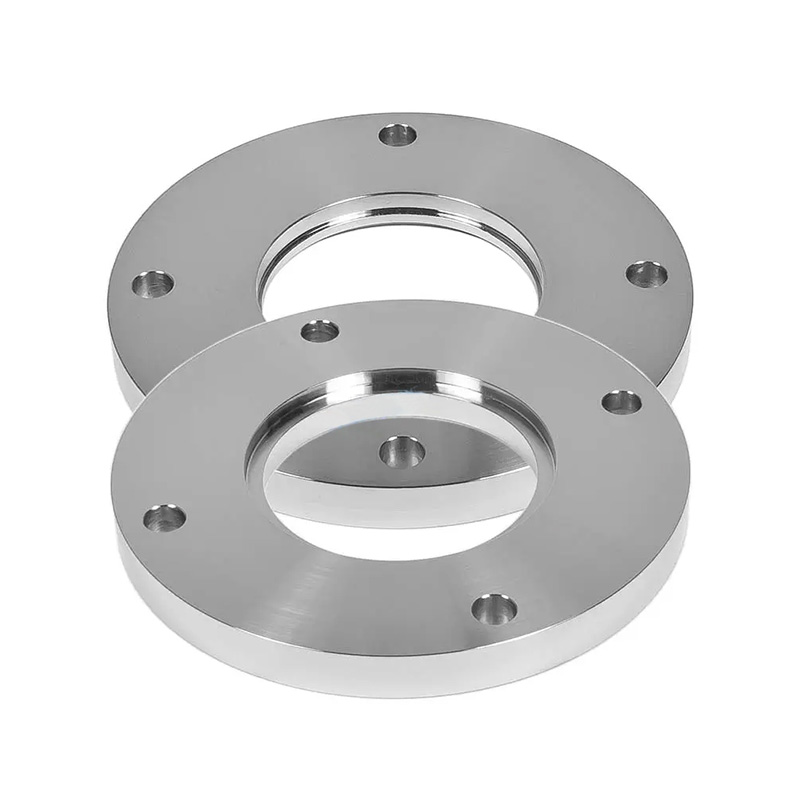

Vacuum flange components are critical elements used in multiple manufacturing applications that require the upkeep of a vacuum environment. These flanges provide a tight and hermetic seal between different parts of a vacuum system, ensuring that the desired low-pressure conditions are met and maintained. Constructed from robust materials like stainless steel, the configuration and surface finish of vacuum components are critical for their performance, as any defects can lead to leaks that compromise the system's efficiency.

In the manufacturing sector, vacuum components are commonly utilized in processes such as thin-film deposition, chemical vapor deposition, and e-beam welding. These applications rely on accurate vacuum conditions to produce high-quality results. For instance, in semiconductor fabrication, maintaining ultra-high vacuum levels is vital to avoid contamination and maintain the purity of the output. The ability to rapidly assemble and take apart negative pressure systems using components also contributes to enhanced productivity and flexibility within manufacturing settings.

Moreover, the flexibility of vacuum components is apparent in their conformity with various vacuum standards, such as International Organization for Standardization and Klein Flange types. This uniformity allows for simple incorporation into current setups and facilitates modifications or enhancements as technology advances. As industries continue to evolve, the role of vacuum components will remain crucial in supporting advancements and enhancing operational capabilities across multiple sectors.

Applications in Industrial Settings

Vacuum seals play a key role in multiple industrial applications that require managed environments. In semiconductor manufacturing, for example, they are used to create vacuum systems that facilitate processes such as chemical deposition and subtractive fabrication. These processes demand precise control over pressure and environment to ensure top-notch production of semiconductors. Vacuum flanges help maintain integrity in these systems, allowing for smooth operations while minimizing contamination risks.

In the realm of pharmaceuticals and biochemical engineering, vacuum flanges are indispensable for applications such as freeze-drying. During this process, water is removed from the product under vacuum conditions which protects the material's structure and effectiveness. The use of proper vacuum flanges is vital in maintaining the required pressure levels and preventing gases escaping, thus ensuring a efficient drying process that meets industry standards.

Additionally, vacuum flanges are integral in the field of materials science where they are employed in film deposition methods. Industries that specialize in coatings often make use of vacuum flanges to create the required vacuum environment for deposition techniques including sputtering and thermal deposition. These applications benefit from the reliability and longevity that vacuum flanges provide, enabling premium coatings on multiple substrates key for innovative materials development.

Benefits of Using Vacuum Flanges

A key benefits of using vacuum flanges is the ability to create a trustworthy and airtight seal. This is vital in various industrial processes where preserving a vacuum is crucial for the efficacy of operations. Top-tier vacuum flanges can withstand significant pressure differences, stopping leakage and contamination. This feature significantly enhances the performance of systems such as vacuum chambers and reactors, where even the tiniest leak can result in product failure or less than ideal conditions.

Furthermore, is the flexibility of vacuum flanges in varied applications. They come in multiple sizes and materials, permitting them to be customized to specific needs across varied industries such as pharmaceuticals, semiconductor manufacturing, and food processing. This adaptability ensures that companies can obtain appropriate flanges for their individual requirements, resulting in improved operational flexibility and reduced downtime due to malfunctions or maintenance issues.

Finally, employing vacuum flanges contributes to overall safety in the workplace. Correctly sealed systems minimize the risk of hazardous material leaks, safeguarding both workers and the environment. Additionally, the employment of reliable vacuum connections helps to stop accidents related to pressure fluctuations that can occur during operation. By confirming safe and efficient processes, vacuum flanges play a critical role in enhancing safety standards across multiple industrial settings.